From Concept to Completion: The Process of Custom Signage Manufacturing

Ever wonder what steps are involved in sign manufacturing? To create custom electric signs, manufacturers follow meticulous steps to create unique and eye-catching signs that meet their client’s specific requirements. Each stage requires careful attention to detail and precision, from design conceptualization to final installation. Once the sign is ready, proper crating and shipping procedures ensure safe delivery to the intended destination where the sign is then installed. Let’s break it down –

CONSULTATION AND DESIGN

First, the sign manufacturer meets with the client to understand their needs, branding requirements, and what they want the sign to achieve. The manufacturer’s design team collaborates with the client to create a concept that captures their vision while incorporating practical considerations such as size, materials, and electrical components.

When a client already has a logo design for their sign, the sign manufacturer plays a crucial role in transforming the logo into an appropriate signage solution that aligns with the client’s specific needs. The manufacturer then utilizes their expertise and knowledge to ensure that the client’s logo is effectively translated into a visually appealing and functional sign that fits the desired space.

ENGINEERING

Once the design is finalized, the engineering team evaluates the concept’s feasibility and functionality. They ensure that the sign will comply with local regulations and electrical standards. Prototyping is an option that may be undertaken to test the design, assess its durability, and ensure proper illumination and visibility.

MATERIALS AND FABRICATION

Now it’s time to bring the design to life! Materials commonly used include aluminum, steel, acrylic, and various lighting components such as LEDs, fluorescent lamps, and neon. Skilled artisans employ cutting, bending, welding, and other fabrication techniques to shape and assemble the sign’s components.

ELECTRICAL WIRING AND INSTALLATION

The electrical aspect of the sign is crucial, and experienced electricians handle this part of the process. They install the necessary electrical components, such as transformers, LED modules, wiring, and controllers, ensuring proper functionality and adherence to safety standards. Quality control checks are performed to verify the electrical connections and ensure everything is in working order.

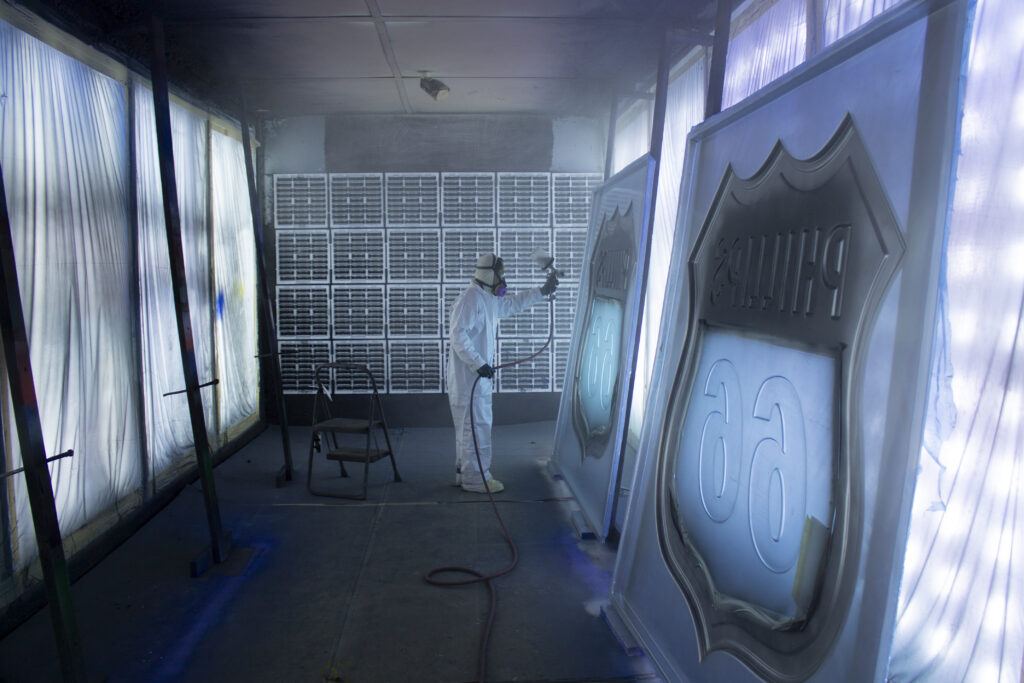

FINISHING AND PAINTING

With the fabrication and wiring complete, the sign goes through a finishing process. This involves sanding, priming, and applying a durable finish to protect the sign from external elements. Custom paint colors and textures are used to achieve the desired aesthetic appearance, often reflecting the client’s branding guidelines.

PACKAGING AND CRATING

Once the sign is ready, it is prepared for shipping. Specialized packaging techniques help to protect the sign during transportation. A wooden crate or sturdy custom-made packaging is used depending on the sign’s size, weight, and fragility. The crate minimizes movement, provides shock absorption, and protects against environmental factors.

SHIPPING AND LOGISTICS

Shipping logistics are an essential part of the process. Proper documentation and labeling accompany the package, indicating fragile contents and handling instructions. The shipping method chosen may vary based on factors like the sign’s size, weight, destination, and delivery schedules.

INSTALLATION

Once the sign arrives at its destination, experienced technicians take charge of the installation. They follow precise instructions and adhere to safety standards while ensuring proper electrical connections and structural stability. The installation may involve wiring the sign to the electrical grid, securing it to the desired location, and conducting final checks to ensure optimal functionality.

IN CONCLUSION

Custom electric sign manufacturers take a step-by-step approach to creating high-quality signs that meet their client’s unique needs. From consultation and design to installation, each stage requires attention to detail and specialized skills to produce visually appealing and long-lasting signs.