Recruiting and Training the Next Generation of Signmakers

IN HOUSTON, AMERICA’S FOURTH largest city, a recent job for a journeyman sign installer for Federal Heath (Euless, TX) remained open for more than three years. The company’s inability to fill the position, according to Director of Human Resources Ryan Bailey, represents more the rule than the exception, as Federal Heath, a sign company with a national reach, has encountered this difficulty in every city, state and region in which they operate. If Federal Heath can’t find an installer in one of the nation’s largest cities, how are other sign companies faring as they search for new fabricators and installers?

Anecdotally, the answer seems to be “not very well.” In late August of last year, Bailey joined fellow sign professional Eric E. Larsen, lead designer of the historic theatre marquee division for Wagner Electric Sign Co. (Elyria, OH), to present a webinar, “Recruiting + Training the Next Generation of Signmakers.” The interest on the part of the attendees, their questions and comments suggested that Federal Heath’s challenge in Houston is widely shared.

SOME CAUSES

How has the industry ended up in this position? Why are we having such difficulty bringing new people, especially young people (who are not family members), into our industry?

One reason seems to be the lack of knowledge among the general public that the sign industry even exists. Though perhaps overstated, ask anyone who’s never worked for a sign company or ordered signs, and they’re not likely to know where signs come from.

Many other professions as large as the sign industry aren’t cloaked in such invisibility. So clearly, one major problem is lack of industry self-promotion. Associations can help, but signshops themselves must do a better job of marketing what they do not only to their clients, but also to their communities.

Money solves many problems, but most sign companies are not in the position to raise salaries for fabricators and installers, and even if they were, they still would be hard-pressed to find the individuals with the skillsets to merit higher pay. Those with skills are closely guarded by the companies they work for, with some shops begging their older, experienced installers to stick around, not to retire, or to continue working part-time. This also can work for a while, but not for the long term.

GET SCHOOLED

So now what? Larsen, the driving force behind the aforementioned webinar, has proposed we return to an age-old system: apprenticeships. Sign companies could recruit from a number of sources, but Wagner Electric will be looking to local high schools, a resource found everywhere. Larsen specifically suggests searching for student-apprentices through high school art teachers.

The art teachers Larsen has talked to so far raised important, legal steps when contacting students under 18. “The art teachers said to give them what you’re looking for [a paid apprentice for summer], and they would find the kids who might be interested,” Larsen said. The art teacher would get back to the sign company with brief descriptions of kids (no names yet) who might be a good fit based on what they’ve been good at in art class. Next, the sign company would reply to the art teacher as to which student(s) they would like to interview. The art teacher would then approach the student(s) and tell them that a sign company is interested in interviewing them for a summer apprenticeship program, with no obligation. If the student(s) are interested, the teacher then would then contact the parents or guardians of those students, and finally, the parents contact the sign company. “There is a lot of contacting back and forth but these are the rules involving minors,” Larsen said.

Also, obviously, any in-shop apprenticeship program would have to be demonstrably safe from potential exposure to COVID-19, as it would be for all employees.

With students over 18 (most in college, for example), you can approach them directly. Many colleges offer art courses and/or art degrees, and present a viable resource for shops in towns near community colleges or universities.

FOR STARTERS

While Larsen and Mark Wagner, president of Wagner Electric Sign Co., are committed to a summer apprenticeship program, they are still discussing exactly what an apprentice might do in their full-service shop. No matter where their apprentice starts, Larsen intends to show the young person everything the company does, even though the apprentice won’t yet be performing the more highly skilled work. “Make sure they realize they’re only at the starting point,” Larsen said, “and this is the other stuff they can do once we get them started and they understand it.” Tell them, he said, “If you see something over in the corner that looks like fun to you, by all means we’ll introduce you to it and see how you do. But [first] we’ve got to get them in the door.”

Where might apprentices start in a shop? Like any entry-level position – at the beginning. Give them the most basic tasks to start on: cutting vinyl and simple applications. In fact, shops may prefer an apprentice doing the easy stuff to free up full-time fabricators to concentrate on more advanced work. Larsen has already enlisted two other, smaller local signshops in the apprenticeship concept. “The sign companies I’m talking to are on board with it because they’re [saying], ‘We need someone to do vinyl this summer,’” Larsen said.

JUSTIFIED

Sure…” I can hear some understandably skeptical readers saying. “But how much time am I going to have to put into training an apprentice, and am I going to get at least that much time back out of them doing sellable work?” Excellent question, and one you can probably already answer by calculating the training period for your most-recent hire or even yourself. Depending on what your shop does, chances are good you can find some kind of work befitting an apprentice.

“Okay,” you may say. “What if they quit or leave at the end of the summer and don’t come back?” Less excellent this time. Are these not the risks of every new hire? Also, don’t many companies hire kids for summer jobs with no expectation of their staying on? Besides, as Larsen said, “If we don’t take those chances, we’re not going to find out and we’ll be stuck in the same boat.”

Now here’s a question for the skeptics: What if the apprentice does produce more hours of sellable work than your hours spent on training? What if they like the job and stay for the entire summer? “Some kids may even decide at the end of the summer that they want to keep working for the sign company, after school or on the weekends,” Larsen said. Some apprentices – the high school seniors – will likely have already graduated by the time they are starting in the summer. Some may either not be, or not yet be, continuing with college, and they could be open to staying on. Even those attending college in the area may want to continue to work while going to school.

More potential benefits: “The kids who are in the program – some will tell their friends,” Larsen said. “Word of mouth travels fast with kids.” Sounds like the kind of promotion the sign industry needs.

PAY TO PLAY

Now for something not completely different, but certainly different enough from the paid-apprentice concept. Sean Heffner, owner of Chicago Wrap (Naperville, IL), also brings new people into his company – but they pay him for training. “The [Chicago Wrap] university is definitely a big thing,” Heffner said. “In one year I’ve probably gotten 60 people into the industry and I’ve hired three or four of them. What I’ve realized is that there’s no one really out there giving that true wrap-shop training.”

Heffner’s father, Mike, originally a pinstriper, started the company in 1980, and a few years ago, recognizing the shortage of skilled wrappers, he and Sean slowly built a training program. They started with one of shop’s old Transit vans, which had lost its transmission. “Rather than just get rid of it, we stripped it, cut it in half and built this wrap course,” he said. Now, Chicago Wrap University offers both at-home courses as well as in-shop, hands-on training.

They’d been at it a couple of years when, in 2018, Heffner decided to accompany his best friend, who was changing careers, to an Avery Dennison wrap seminar in Miami. “With 17 years of experience I went to the class and I learned a lot beyond just how to put wraps on,” Heffner said. “What I learned personally was humility. That was from Justin Pate, and that’s what [further] sparked my interest.” Upon his return home, Heffner looked to improve the wrap course.

COURSE OF ACTION

The first thing Heffner realized at the seminar in Miami was that two days isn’t enough, so Chicago Wrap extended their training to two weeks. The first week emphasizes classroom training and the fundamentals of vinyl. “Then we get [students to start applying vinyl] on the wall, so they’re going back and forth, which is similar to the [manufacturers’] class,” Heffner said. “We keep pounding the fundamentals into them, and then for the second week, we get them working on an actual car, usually one of our customers’ vehicles. Now they’re getting actual experience, real-life certification, and when they’re done, they feel like they did the car,” he said, adding, “It’s very important to get that first wrap under your belt, and then you just keep going.”

Once students complete the course, they can come back and, with guidance, wrap another vehicle. “I give them the opportunity to do their own vehicle or their first customer’s,” Heffner said.

“It’s almost like an extra for the course, because we want to stand behind these guys and answer for our certification.” Heffner sees this as differentiating Chicago Wrap U. from manufacturers’ training and certification, which, after their seminars, generally allow their students a year to earn their certifications. “We deliver that at the end of the second week,” Heffner said.

As proof, he related an anecdote of some of his graduates who went to 3M for certification on installing clear bra. Heffner said his students passed on their first try despite the instructors’ having insisted that a background of five years in wrapping would be necessary. “Where the hell did you learn to wrap?” the instructors are reported to have said.

NETWORK OF SUCCESS

When asked, aren’t you just training your competition? Heffner answered, “That’s what everyone says. The way I look at it is, the wrap industry is in need of installers and a wrap company needs installers more than [any other kind of employee].” He said he’s encountered some “arrogant people,” who have opened wrap shops in his area, but he’s not bothered. “I want more people to do it,” Heffner said. “Competition is always going to be out there. [To succeed], it comes down to knowing how to run a business.”

He credits the commitment to his installers for putting him in a position to teach. “And it’s the most profitable part of my business right now,” he said. In addition to the revenue, Chicago Wrap’s graduates also comprise a network of installers Heffner can call upon. “Sometimes I’ve had more installers than I can use, sometimes less, but there’s nothing worse than having to turn down a job because you don’t have enough installers,” he said. “And when you get jobs, deadlines are tight,” as was the case with a big job for the 2019 Chicago Auto Show.

Should other companies follow this lead? “If they’re big enough and can take on the responsibility and have the facility and the installers… it would be beneficial to them because they’re going to bring in more people and build their own networks,” Heffner said.

Like many in the sign industry, Heffner was born into it, but we can’t continue to allow that to continue to be the best or primary means to enter the field. “There are a lot of kids out there interested in this industry,” he said, “but I don’t think they know what to do.”

Now, hopefully, you have a few ideas.

This article appeared in SOT (Signs of the Times) magazine, March 14, 2021. Read the original here.

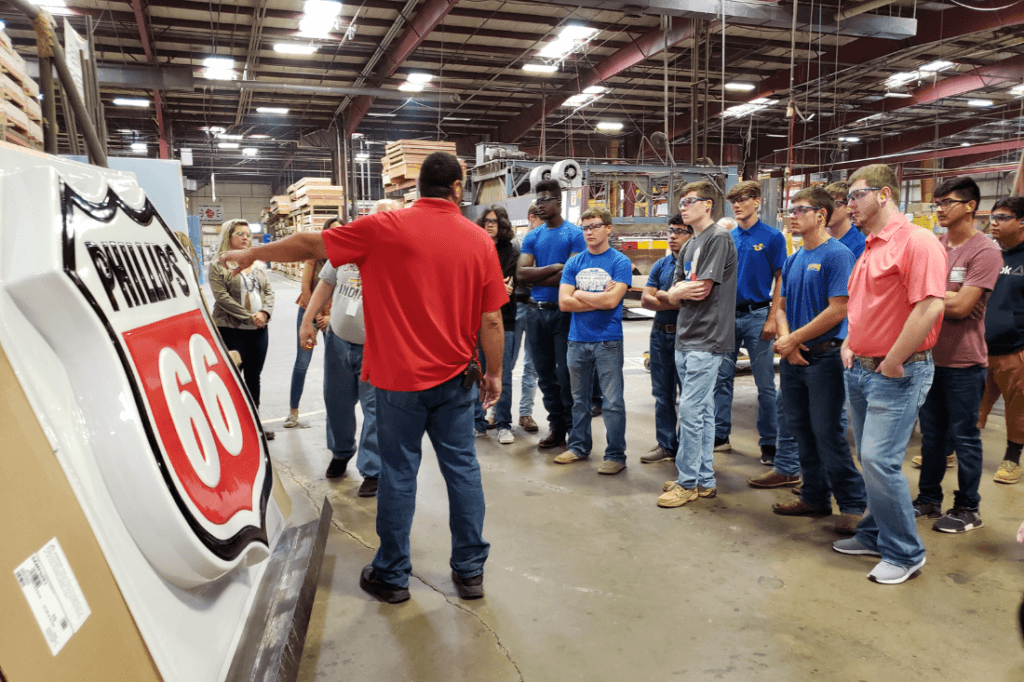

Here’s another way to introduce your shop to young people, but with a less-involved commitment: Sign Manufacturing Day, held annually across the US and Canada on the first Friday in October. This event draws thousands of students to tour sign, graphics and visual communications companies, and to learn more about careers in the industry. Participating students have found permanent jobs, internships and co-ops, and participating companies have built ongoing relationships with educators and schools. The event is sponsored by ISA in conjunction with the National Association of Manufacturers. Learn more at signs.org.

To view open positions at Federal Heath, click here.